Wednesday, March 8, 2023

Altium Designer: An Overview of the Leading PCB Design Software

Tuesday, March 7, 2023

Understanding Pull-Up Resistors: A Guide to Their Function and Use

Monday, March 6, 2023

Decoupling Capacitors: Their Importance and Usage in Electronics Circuits

Decoupling capacitors are an essential component of electronics circuits that are used to filter out unwanted noise and provide stable power to integrated circuits. These capacitors are placed close to the power supply pins of integrated circuits to prevent power supply noise and voltage fluctuations, which can cause malfunctions or even damage the circuit.

Integrated circuits are very sensitive to voltage fluctuations and noise in the power supply, which can lead to errors in the circuit operation or even destroy the circuit. This is where decoupling capacitors come into play. They store electric charge and release it when the voltage across the capacitor changes. When the voltage across the power supply pin of an integrated circuit drops, the decoupling capacitor releases its stored charge to maintain a constant voltage level. Similarly, when the voltage rises above a certain level, the decoupling capacitor absorbs excess charge to prevent the voltage from becoming too high.

Decoupling capacitors also filter out high-frequency noise that can affect the performance of the circuit. High-frequency noise is generated by digital circuits, and it can cause electromagnetic interference (EMI) in the circuit. Decoupling capacitors act as a low-pass filter and prevent high-frequency noise from reaching the integrated circuits.

The importance of decoupling capacitors cannot be overstated. They are a crucial component of electronics circuits, especially for high-speed digital circuits. Without them, the circuit may suffer from voltage fluctuations and power supply noise, which can cause malfunctions and other problems.

When selecting decoupling capacitors, it's essential to choose capacitors with appropriate capacitance values and high-frequency characteristics. The capacitance value should be selected based on the current requirements of the circuit, and the high-frequency characteristics of the capacitor should match the frequency range of the noise to be filtered.

In conclusion, decoupling capacitors play a critical role in electronics circuits by providing a stable power supply and filtering out unwanted noise. They are a vital component for ensuring the proper functioning of integrated circuits and preventing damage to the circuit. With proper selection and usage, decoupling capacitors can significantly improve the performance and reliability of electronics circuits.

Thursday, March 2, 2023

OpenCV: An Introduction to Computer Vision

OpenCV: An Introduction to Computer Vision

Computer Vision is an interdisciplinary field that deals with how computers can be made to gain high-level understanding from digital images or videos. It involves extracting useful information from visual data, which can be used in a wide range of applications, such as object recognition, face detection, autonomous vehicles, and medical image analysis. OpenCV (Open Source Computer Vision) is a popular library of programming functions mainly aimed at real-time computer vision applications. In this blog post, we will discuss OpenCV, its history, features, and some of its applications.

History of OpenCV

OpenCV was initially developed by Intel in 1999, and later, in 2000, it was released as an open-source project under the BSD license. The first version of OpenCV (version 0.1) was written in C and was mainly used in research projects. However, as the library grew, it was rewritten in C++, which improved its performance and made it easier to use. In 2006, Willow Garage, a robotics research lab, took over the development of OpenCV and continued to improve and expand it.

Features of OpenCV

OpenCV is a versatile library that supports a wide range of programming languages, including C++, Python, and Java. It provides over 2500 optimized algorithms that can be used to perform various computer vision tasks, such as image processing, object detection, and feature extraction. Some of the features of OpenCV are:

- Image and Video I/O: OpenCV can read and write images and videos in various formats, such as JPEG, PNG, BMP, AVI, and MP4.

- Image Processing: OpenCV provides a set of functions for image processing, such as filtering, thresholding, and morphological operations.

- Feature Detection and Description: OpenCV provides algorithms for detecting and describing features in images, such as corners, edges, and blobs.

- Object Detection and Tracking: OpenCV provides several algorithms for object detection and tracking, such as Haar Cascade Classifiers and CamShift.

- Machine Learning: OpenCV provides a module for machine learning, which includes various algorithms for classification, regression, and clustering.

Applications of OpenCV

OpenCV is widely used in computer vision research and applications. Here are some of its applications:

Robotics: OpenCV is used in robotics for navigation, object recognition, and obstacle avoidance.

Autonomous Vehicles: OpenCV is used in autonomous vehicles for lane detection, pedestrian detection, and traffic sign recognition.

Medical Image Analysis: OpenCV is used in medical image analysis for segmentation, registration, and diagnosis.

Security: OpenCV is used in security applications for face recognition, object tracking, and intrusion detection.

Entertainment: OpenCV is used in entertainment applications, such as video games and augmented reality.

Conclusion

In conclusion, OpenCV is a powerful library for computer vision applications, and its popularity is increasing day by day. Its extensive set of functions and algorithms make it a versatile library that can be used in various applications. OpenCV is constantly being improved and updated by its community of developers and contributors, which makes it a reliable and robust library for computer vision research and applications.

Wednesday, March 1, 2023

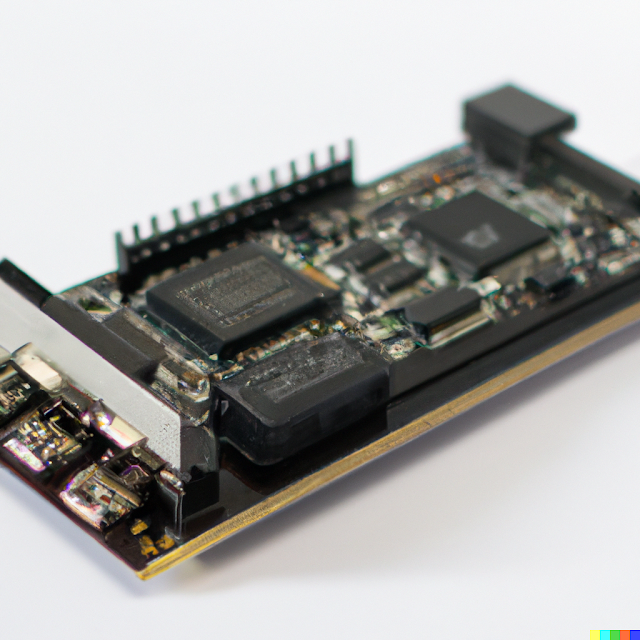

What are FPGAs?

Field-Programmable Gate Arrays (FPGAs) are a type of integrated circuit that are designed to be programmable and reconfigurable. Unlike Application-Specific Integrated Circuits (ASICs), which are designed for a specific application, FPGAs can be programmed and reconfigured to perform a wide range of functions.

FPGAs consist of programmable logic blocks and interconnects that can be programmed to implement a digital circuit. The programming is typically done using a hardware description language (HDL) such as Verilog or VHDL.

FPGAs are often used in prototyping and development, as they offer a fast and flexible way to test and iterate on designs. They are also used for hardware acceleration in high-performance computing applications, where they can provide significant performance improvements over traditional CPUs.

Advantages of FPGAs

FPGAs offer several advantages over other types of integrated circuits, including:

- Reconfigurability: FPGAs can be reprogrammed to perform different functions, making them highly flexible and adaptable.

- Prototyping: FPGAs are often used in prototyping and development, as they offer a fast and flexible way to test and iterate on designs.

- Hardware Acceleration: FPGAs can be used for hardware acceleration in high-performance computing applications, where they can provide significant performance improvements over traditional CPUs.

Applications of FPGAs

FPGAs are used in a wide range of applications, including digital signal processing, image processing, networking, and high-performance computing. They are particularly useful in applications that require high performance, low latency, and flexibility.

In digital signal processing, FPGAs are used to implement filters, FFTs, and other signal processing functions. In image processing, FPGAs are used to implement image compression and decompression algorithms.

In networking, FPGAs are used in routers, switches, and other network devices to implement packet processing and other network functions. In high-performance computing, FPGAs are used for hardware acceleration of scientific simulations, machine learning algorithms, and other compute-intensive applications.

In conclusion, FPGAs are a type of integrated circuit that offer a high degree of flexibility and adaptability. They are used in a wide range of applications, including digital signal processing, image processing, networking, and high-performance computing. FPGAs provide a critical component for many modern devices and systems, and their flexibility and programmability make them a powerful tool for prototyping, development, and hardware acceleration.

Tuesday, February 28, 2023

What are ASICs?

ASIC stands for Application-Specific Integrated Circuit. As the name implies, ASICs are integrated circuits (ICs) that are designed for a specific application or function. Unlike general-purpose ICs, which can be used in a wide variety of applications, ASICs are custom-designed to perform a specific task or set of tasks.

ASICs can be designed to perform a wide range of functions, including digital logic, analog circuits, and mixed-signal circuits. They can be used in a variety of applications, including telecommunications, consumer electronics, automotive, and aerospace.

ASICs are typically designed using specialized software tools and programming languages. The design process involves creating a detailed specification for the ASIC, followed by designing and verifying the circuitry. Once the design is complete, the ASIC is manufactured using semiconductor fabrication processes.

ASICs vs. FPGAs

Field-Programmable Gate Arrays (FPGAs) are another type of integrated circuit that are often used for custom applications. While ASICs are custom-designed and manufactured for a specific application, FPGAs are reconfigurable and can be programmed to perform different tasks.

FPGAs are often used in prototyping and development, as they offer a fast and flexible way to test and iterate on designs. However, ASICs offer several advantages over FPGAs in terms of performance, power consumption, and cost.

Advantages of ASICs

ASICs offer several advantages over other types of integrated circuits, including:

- Performance: ASICs can be optimized for a specific application, which can result in higher performance than general-purpose ICs.

- Power Consumption: ASICs can be designed to minimize power consumption, which is particularly important in battery-powered applications.

- Cost: Although ASICs have higher upfront design costs than general-purpose ICs, they can be more cost-effective in the long run due to their optimized performance and lower power consumption.

Applications of ASICs

ASICs are used in a wide range of applications, including telecommunications, consumer electronics, automotive, and aerospace. They are particularly useful in applications that require high performance, low power consumption, and specialized functionality.

In telecommunications, ASICs are used in a variety of applications, including modems, routers, and wireless communication systems. In consumer electronics, ASICs are used in smartphones, tablets, and digital cameras.

In automotive and aerospace, ASICs are used in a variety of systems, including engine management, safety systems, and avionics.

In conclusion, ASICs are powerful and versatile integrated circuits that are designed for a specific application or function. They offer several advantages over other types of integrated circuits, including optimized performance, low power consumption, and cost-effectiveness. ASICs are used in a wide range of applications, from telecommunications to consumer electronics to automotive and aerospace, and provide a critical component for many modern devices and systems.

Sunday, February 26, 2023

What are Microcontrollers?

A microcontroller is a type of integrated circuit (IC) that contains a small computer on a single chip. It is designed to control a specific function or system, and is used in a wide variety of applications such as embedded systems, robotics, and automation.

Microcontrollers typically have built-in peripherals that allow them to interact with the external world. These peripherals include inputs such as analog-to-digital converters (ADCs) and digital-to-analog converters (DACs), as well as outputs such as pulse-width modulation (PWM) and digital I/O.

The use of interrupts is another key feature of microcontrollers. Interrupts allow the microcontroller to respond to external events in real-time, rather than constantly polling for changes. This makes microcontrollers well-suited for applications that require real-time responsiveness, such as control systems and sensors.

Microcontrollers are programmed using specialized software tools and programming languages. The code is typically written in a high-level language such as C or C++, and is then compiled and loaded onto the microcontroller using a programmer or debugger.

Applications of Microcontrollers

Microcontrollers are used in a wide variety of applications. They are commonly used in embedded systems, which are computer systems that are integrated into other devices. Examples of embedded systems include home appliances, medical devices, automotive systems, and industrial automation.

In robotics, microcontrollers are used to control the movement and behavior of robots. They can be used to control motors, sensors, and other peripherals to create autonomous robots that can navigate through their environment and perform various tasks.

In automation, microcontrollers are used to control and monitor various systems such as heating and cooling systems, lighting systems, and security systems. They can be programmed to respond to various inputs, such as temperature or motion sensors, and to perform specific actions based on those inputs.

In conclusion, microcontrollers are powerful and versatile integrated circuits that are widely used in a variety of applications. They are essential components of embedded systems, robotics, and automation, and provide real-time responsiveness and control over peripherals. Microcontrollers offer a cost-effective and efficient way to implement complex functionality in a wide range of devices and systems.

What is an In-Circuit Component Tester (ICT) System?

An In-Circuit Component Tester (ICT) system is a type of automated test equipment used to test printed circuit board (PCB) assemblies. The ICT system is designed to test both analog and digital components on the PCB while the components are in-circuit.

The ICT system typically consists of a test fixture, which holds the PCB assembly, and a tester, which is used to perform the tests. The test fixture is designed to make contact with the test points on the PCB assembly and to provide a stable and consistent test environment.

The tester is designed to perform a variety of tests on the PCB assembly, including boundary scan, functional testing, and analog and digital component testing. The boundary scan test is used to test the interconnectivity of the components on the PCB assembly. Functional testing is used to test the functionality of the PCB assembly, and analog and digital component testing is used to test the individual components on the PCB assembly.

ICT systems are used in a variety of applications, including manufacturing and quality control. They are used to ensure that the PCB assemblies meet the required specifications and quality standards.

ICT systems are particularly useful for testing PCB assemblies that have a high density of components or that have components that are difficult to test using other methods. They are also useful for testing PCB assemblies that have a high level of complexity or that are used in critical applications where reliability is paramount.

In manufacturing applications, ICT systems are used to test PCB assemblies before they are shipped to customers. This ensures that the PCB assemblies meet the required specifications and quality standards and helps to prevent costly recalls or warranty claims.

In quality control applications, ICT systems are used to test PCB assemblies that have been returned by customers or that have failed during the manufacturing process. This helps to identify and correct any issues with the PCB assemblies before they are shipped to customers.

In conclusion, ICT systems are essential tools for testing PCB assemblies in manufacturing and quality control applications. They provide valuable data that can be used to improve processes, optimize performance, and ensure compliance with regulatory requirements.

Data Logger Systems

A data logger is a device that records data over time. It is used to monitor and track various parameters such as temperature, humidity, pressure, voltage, current, and other environmental conditions. The data logger typically consists of a sensor, a microprocessor, and a memory chip.

The sensor is used to measure the parameter being monitored, and the microprocessor converts the sensor data into digital signals that are stored in the memory chip. The data logger can be programmed to sample data at different intervals, from seconds to hours or even days.

Data loggers are used in a variety of applications, including environmental monitoring, industrial process control, and scientific research. They can be used to track temperature and humidity in a warehouse or storage facility, monitor energy usage in a building, or collect data on water quality in a river or lake.

In environmental monitoring, data loggers are used to measure parameters such as temperature, humidity, air pressure, and light levels. These data loggers can be used to monitor the conditions in a greenhouse or to track the weather in a particular location.

In industrial process control, data loggers are used to monitor and control various parameters such as temperature, pressure, and flow rate. They can be used in manufacturing processes to ensure that products are produced to the desired specifications and quality standards.

In scientific research, data loggers are used to collect data on a wide range of parameters, including temperature, humidity, and light levels. They can be used to study the behavior of animals in their natural habitats, to monitor the conditions in a laboratory, or to track the growth of plants in a greenhouse.

Data loggers can be standalone devices or can be connected to a computer or network for data analysis and storage. They can be battery-powered or can be powered by an external power source, depending on the application requirements. Some data loggers also have built-in wireless connectivity for remote monitoring and control.

In conclusion, data loggers are essential tools for monitoring and tracking various parameters in a wide range of applications. They provide valuable data that can be used to improve processes, optimize performance, and ensure compliance with regulatory requirements.